UNISAFE 𝗣𝗥𝗢 3W 2.0 with upper beam for embankment - H3 and H4b

Reference: UNISAFE 𝗣𝗥𝗢 3W 2.0

- Description

- Technical data

- Downloads

Description

🛡️ UNISAFE PRO 3W 2.0 – H3 and H4b Restraint System – High Performance for High-Risk Roadsides

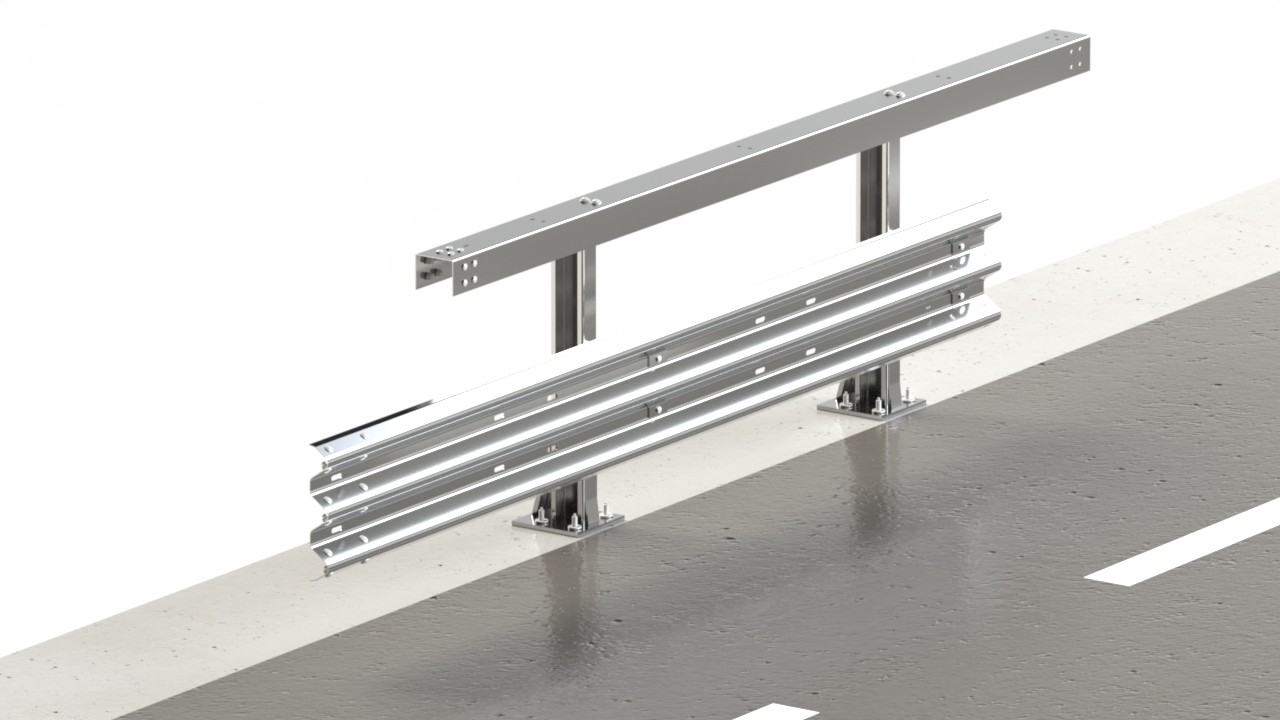

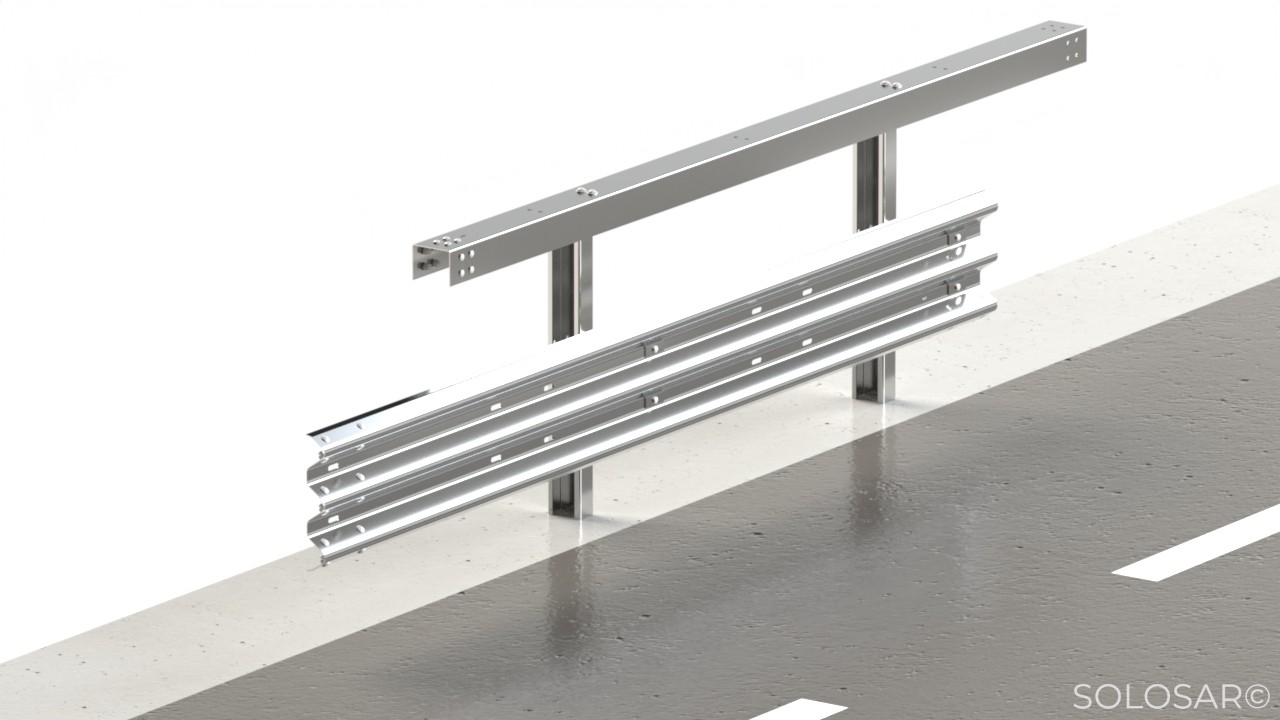

The UNISAFE PRO 3W 2.0, developed by UNIPROMET and distributed by SOLOSAR, is a CE-certified H3 and H4b steel safety barrier designed for roadsides, embankments, and sensitive areas with heavy traffic. Featuring a reinforced triple-wave structure, it delivers very high containment while maintaining an ASI level A, ensuring maximum safety for vehicle occupants.

🔧 Technical Specifications:

| Parameter | UNISAFE PRO 3W 2.0 – H3 | UNISAFE PRO 3W 2.0 – H4b |

|---|---|---|

| Containment level | H3 (EN 1317-2) | H4b (EN 1317-2) |

| Working width | W5: 1.40 m | W5: 1.70 m |

| Dynamic deflection | 1.30 m | 1.60 m |

| Vehicle intrusion | 2.80 m | 1.60 m |

| ASI level | A (best performance) | A (best performance) |

| Beam type | Triple wave | Triple wave |

| System width | 0.41 m | 0.55 m |

| Anchoring depth | 1.01 m | 1.01 m |

| Test length | 81 m | 81 m |

| Installation area | Roadsides, embankments | Roadsides, embankments |

✅ Key Benefits:

-

H3 and H4b containment for high-traffic roads, including heavy vehicles

-

Reinforced triple-wave design for maximum impact resistance

-

ASI A: optimal safety level for vehicle occupants

-

Controlled dynamic deflection: 1.30 m – excellent for H3 level

-

Vehicle intrusion: 2.80 m – suitable for areas with adequate lateral clearance

-

System width: 0.41 m – robust while remaining roadside-compatible

-

Anchoring depth: 1.01 m – ensures strong ground stability (natural soil or fill)

-

Fully compliant with EN 1317-2 European standard

📄 Recommended Applications:

-

Roadsides of expressways, national roads, or motorways

-

Rural or mountainous areas with steep slopes or embankments

-

Environments with frequent heavy or fast vehicle traffic

-

Safety projects in open or high-risk areas

Technical data

UNISAFE PRO 3W 2.0 – Technical Data

-

Containment level: H4b / H3 (EN 1317-2)

-

Working width: W5 (1.7 m in H4b / 1.4 m in H3)

-

Impact Severity Index (ASI): A

-

THIV: according to ITT crash tests (TB11, TB61, TB81)

-

Tested length: 60.00 m + 2 x 10.632 m

-

System width: 0.55 m

-

System height: 1.20 m (± 3 cm)

-

Post spacing: 2.00 m

-

Post embedment depth: approx. 1.01 m (driven installation)

-

Materials: Steel S235JR and S355JR

-

Beam type: triple-wave beam (L = 4320 mm, thickness 2.5 mm)

-

Posts: C-profile 150x90x25x5 mm (L = 2200 mm)

-

Additional components: G300 spacers, fixing brackets, galvanized bolts M10 / M16

-

Corrosion protection: Hot-dip galvanization according to EN ISO 1461

-

Expected durability: ≈ 20 years (depending on climatic and exposure conditions)

-

Soil conditions: installation allowed on soil classes 3 to 5 (DIN 18300) by ramming; on soil classes 6 and 7 by drilling with appropriate backfilling.

-

Installation tolerances:

-

Post spacing: ± 21 mm

-

Alignment over 12 m: ± 30 mm

-

Beam vertical deviation: ± 30 mm

-

Downloads

You may also be interested in these products

Applications

- Roadside steel barriers

- Steel backed timber crash barriers acc. EN 1317-2

- Median steel barriers

- Bridge steel railing

- Crash cushions acc. EN 1317-3

- High performance end terminals acc. XP ENV 1317-4

- Motocyclist Protection Systems

- Pedestrian parapets

- Galvanized Wire Fences

- ASTRA systems and components

- ULTRAGUARD™: a global innovation for road safety